It uses mostly off the shelf components and no welding is required.

The main cage support uses 4 X M16 Stainless steel threaded rods with matching nuts and washers

The platform, mid and top bearing support uses 3 X 8mm thick by 250mm square aluminum plates.

Making it light in weight with no compromise on strength.

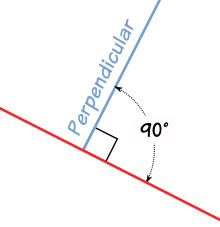

The most important consideration with any type of head unit is that the Rotator platform needs to be perpendicular to the thrust bearing at the top, any misalignment on the bottom platform means that when the stub mast turns in the Rotator it will not be vertical to the middle and top plates and could bind and damage the Rotator.

A picture is worth a thousand words

The beauty of this design is the fact you can align the cage to pin point accuracy because of the thread and nut construction.

The Aluminum plates

The plates with rods screwed in

All plates attached

Topping out time

No comments:

Post a Comment